UV printing on clear acrylic sheets is a popular technique for creating vibrant and high-quality prints on transparent surfaces. UV printing involves using ultraviolet light to cure (harden) ink directly onto the acrylic sheet. Here's a step-by-step guide on how to do UV printing on clear acrylic:

**Materials you'll need:**

1. Clear acrylic sheet

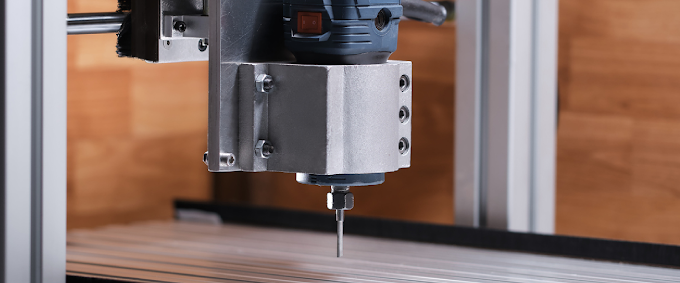

2. UV printing machine (UV flatbed printer)

3. UV-curable ink

4. Computer with design software (e.g., Adobe Illustrator, CorelDRAW)

5. Cleaning supplies (e.g., isopropyl alcohol, lint-free cloth)

6. UV curing system (integrated into the UV printer)

**Step-by-step process:**

1. **Design your artwork**:

Use design software on your computer to create the artwork you want to print on the acrylic sheet. Ensure that your design is sized correctly to match the dimensions of your acrylic sheet.

2. **Prepare the acrylic sheet**:

Clean the surface of the clear acrylic sheet thoroughly with isopropyl alcohol and a lint-free cloth. This will remove any dust, oils, or debris that could interfere with the printing process and result in poor print quality.

3. **Load the acrylic sheet onto the printer**:

Follow the instructions provided by the manufacturer of your UV flatbed printer to load the acrylic sheet securely onto the printing bed.

4. **Set up the printer and ink**:

Make sure your printer is calibrated and ready to print. Fill the printer's ink cartridges with the appropriate UV-curable ink for clear acrylic printing.

5. **Print your design**:

Send the design from your computer to the UV printer. The printer will use UV-curable ink to print your design directly onto the clear acrylic sheet. The ink will be in a liquid state during printing.

6. **Cure the ink**:

As soon as the ink is applied to the acrylic sheet, the UV curing system in the printer will expose the ink to UV light. This exposure will cause the ink to quickly harden and cure, bonding it to the acrylic surface permanently.

7. **Inspect and clean (if necessary)**:

Once the printing process is complete, carefully inspect the printed acrylic sheet for any imperfections or smudges. If you notice any issues, you might need to clean the sheet and reprint the design.

8. **Allow time for full curing**:

While the ink may have hardened during the UV printing process, it's essential to allow the acrylic sheet to sit and cure fully for a few hours or as recommended by the ink manufacturer. This ensures the ink fully adheres to the acrylic and achieves maximum durability.

Always refer to the user manual and guidelines provided by the UV printer and ink manufacturer for specific instructions and safety precautions related to your equipment and materials.

UV printing on clear acrylic results in stunning, visually appealing prints suitable for various applications, such as signage, displays, and decorative elements.

.jpeg)

0 Comments